Eco-Bio PE 5

Eco-Bio PE5 is used for a wide range of applications including:

As a preservative in personal care formulations

As a latex coalescent in water - based architectural and industrial coatings

As a solvent and plasticizer for nitrocellulose, cellulose acetate, ethyl cellulose and many vinyl, phenolic, alkyd and ester - type resins in water - based coatings

As a solvent in printing inks

As an emulsifier to help lower interfacial tension in oil - water emulsions

As an ingredient in slurrying compounds used to protect metals against corrosion

As a synergistic component in broad spectrum anti - bacterial agents

As an additive in paint industry

As a perfume fixative

INCI Name

Phenoxyethanol

Other Names

Ethylene Glycol Phenyl Ether, Phenyl Cellosolve

CAS Number

122-99-6

Chemical Formula

C6H5O-CH2CH2OH

Technical Specifications

Appearance / Nature: Clear, low viscous liquid

Odour: Characteristic

Colour

a) description: Colourless

b) on Lovibond ( 5 ¼ ” cell, on Y+R), maximum: 0.5

pH (1 % aqueous solution): 5.5 - 7.0

Purity, % by GC, minimum: 99.5

Moisture content, % by mass (by KF), maximum: 0.2

Phenoxyethoxyethanol, % by GC, maximum: 0.5

Specific gravity (at 20°C): 1.105 - 1.110

Refractive index (at 20°C): 1.537 - 1.539

Free Phenol, ppm, maximum: 5

Applications

Eco-Bio PE5 is used for a wide range of applications including:

As a preservative in personal care formulations

As a latex coalescent in water - based architectural and industrial coatings

As a solvent and plasticizer for nitrocellulose, cellulose acetate, ethyl cellulose and many vinyl, phenolic, alkyd and ester - type

resins in water - based coatings

As a solvent in printing inks

As an emulsifier to help lower interfacial tension in oil - water emulsions

As an ingredient in slurrying compounds used to protect metals against corrosion

As a synergistic component in broad spectrum anti - bacterial agents

As an additive in paint industry

As a perfume fixative

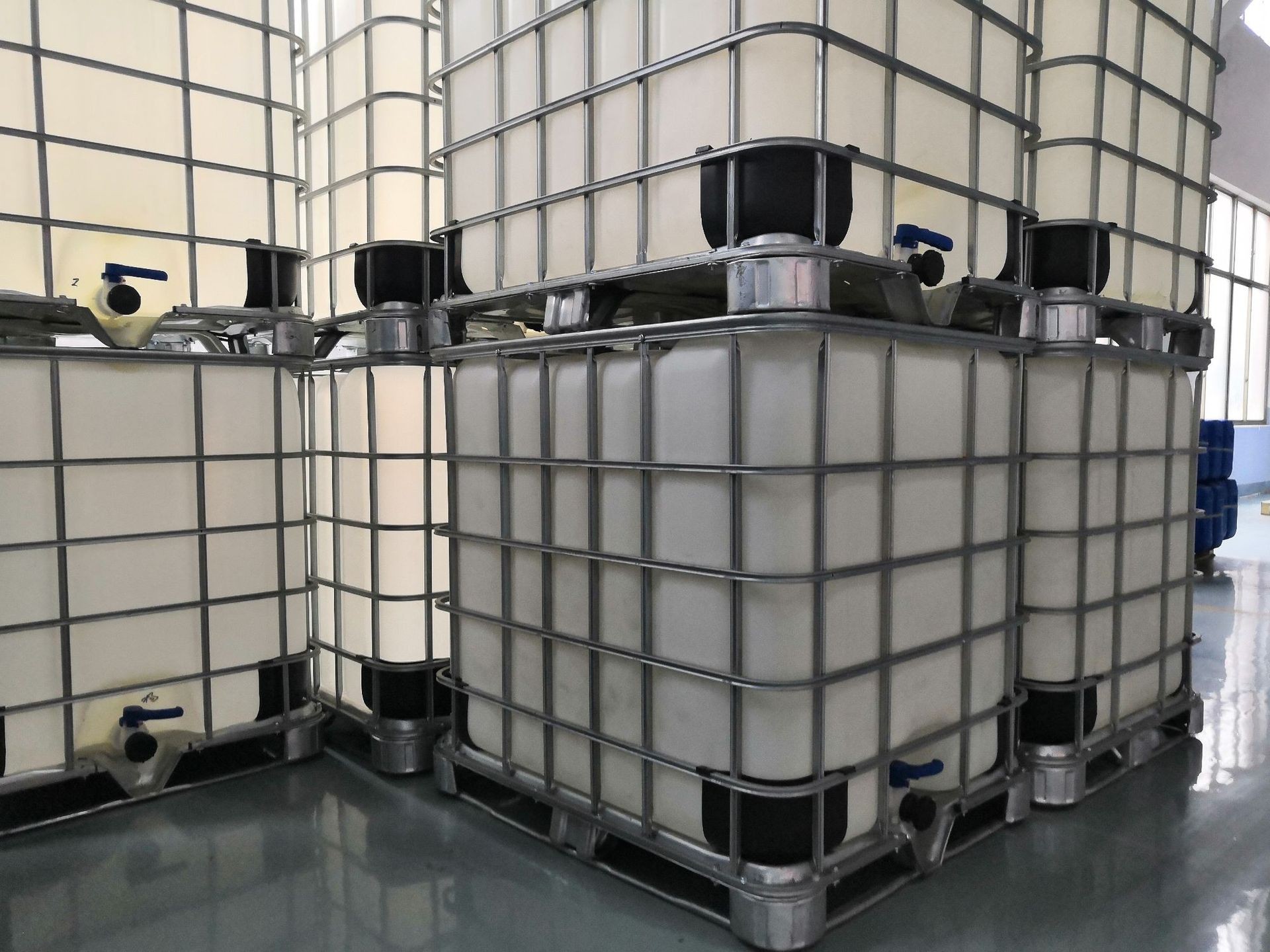

Packing

Eco-Bio PE5 is available in 235 litres HMHDPE carboys. Total of 80 carboys i.e. 20 MT (250 kg per carboy) can be shipped palletized or non - palletized in 20 ft. full container load. It is available in 35 litres HMHDPE carboys. Total of 480 carboys i.e. 16.8 MT can be shipped palletized or non - palletized in 20 ft. full container load. It is also available in 25 litres HMHDPE carboys. Total of 640 carboys i.e. 16 MT can be shipped palletized or non - palletized in 20 ft. full container load. It can be supplied in IBC of 1/1.1 MT capacity. Total of 18 IBC i.e. 18 / 19.8 MT can be shipped in 20 ft. full container load. It can also be shipped in ISO containers.

Handling and Storage

Store the material in a clean, dry place at 20 - 40°C away from direct heat and sunlight. Keep the container tightly closed after use. Since product is hygroscopic in nature, moisture content may increase if exposed to atmosphere, but does not affect preservation properties. Once carboy / IBC is opened, consume the product within a week. Product solidifies, if stored below 14°C for prolonged time. If solidifies, it is recommended to heat ISO containers with hot water or steam with 1.0 - 1.5 kg / cm2 pressure through jacket to bring the temperature of product to 30 - 40°C. If the product becomes frozen in IBC / HMHDPE carboys then keep the same in hot room of 30 - 40°C (avoid direct heating). In original sealed condition, when stored as suggested, shelf life of the product is at least 2.5 years. During storage, stacking should be maximum 1+1 for IBC / HMHDPE carboys (palletized as well as non - palletized).

Spill should be contained / collected and disposed off as per the regulations. Avoid ingestion and contact with skin, eyes and clothing. In case of contact with eyes, rinse with plenty of water and seek adequate and timely medical attention.

INQUIRY

Categories

Contact Us

Contact: Vicky Lin

Phone: +49 (0) 211 9252 810

E-mail: info@ecobiogmbh.de

Whatsapp:

Add: Bahnstr. 9, 40212 Düsseldorf, Germany